Your basket is empty.

| Material: | high quality, deep-drawing, low-carbon, cold rolled DC01 steel sheet in accordance with PN-EN 10130. |

| Spacing of vertical water channels: | 33,3 mm |

| Connections: | 2 x G ½" bottom, right side connectors (left side- available on request) 4 x G ½" side connectors |

| Working pressure: | 10 bar |

| Maximal temperature: | 110°C |

| Test pressure: | 13 bar |

| Colour: | RAL 9016 white, other colours from the RAL colour chart are available on request. |

| Accessories bundled with the radiator: | brackets, plug, air vent |

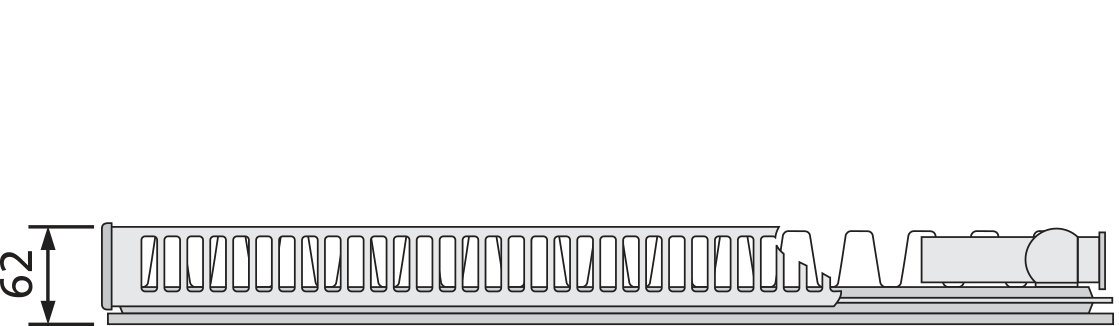

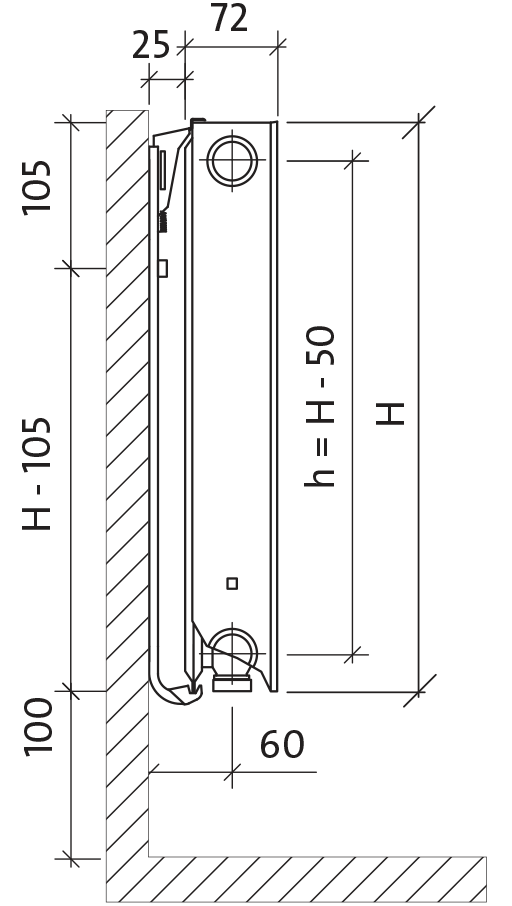

Type 11 |

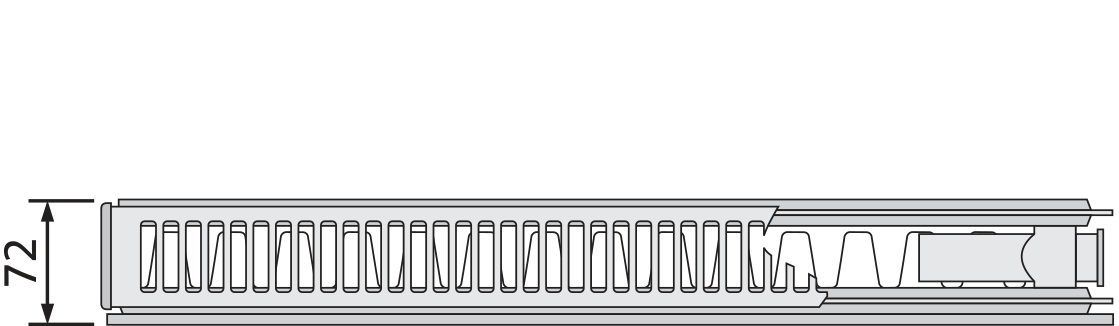

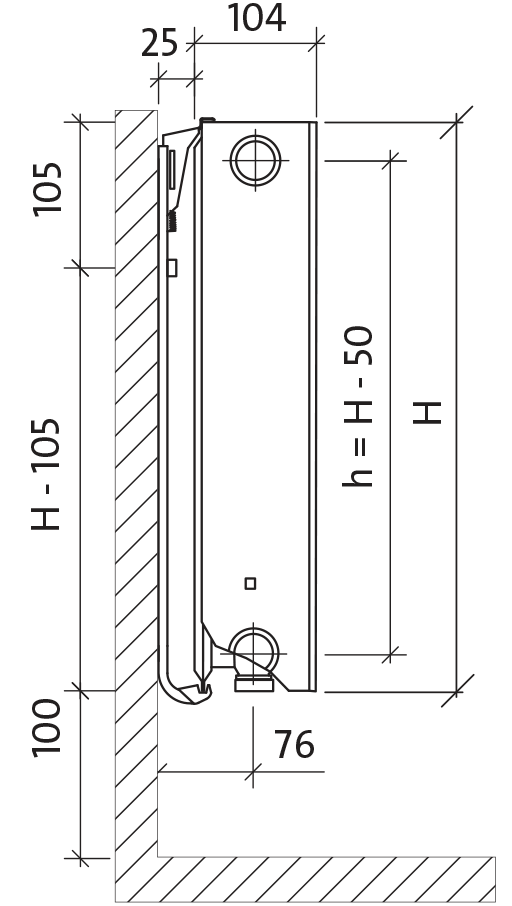

Type 21s |

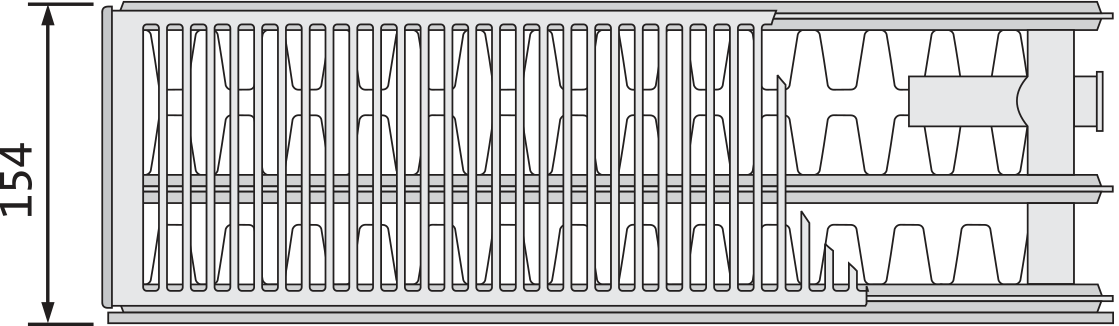

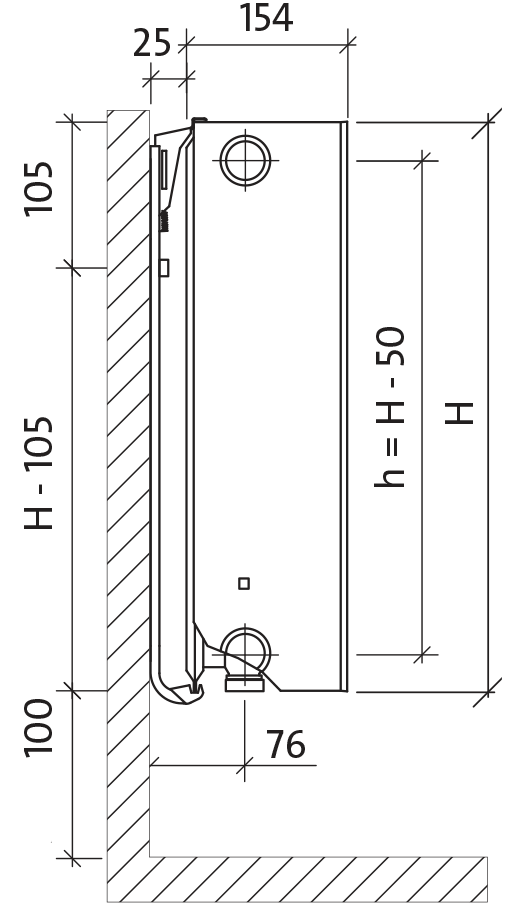

Type 22 |

Type 33 |

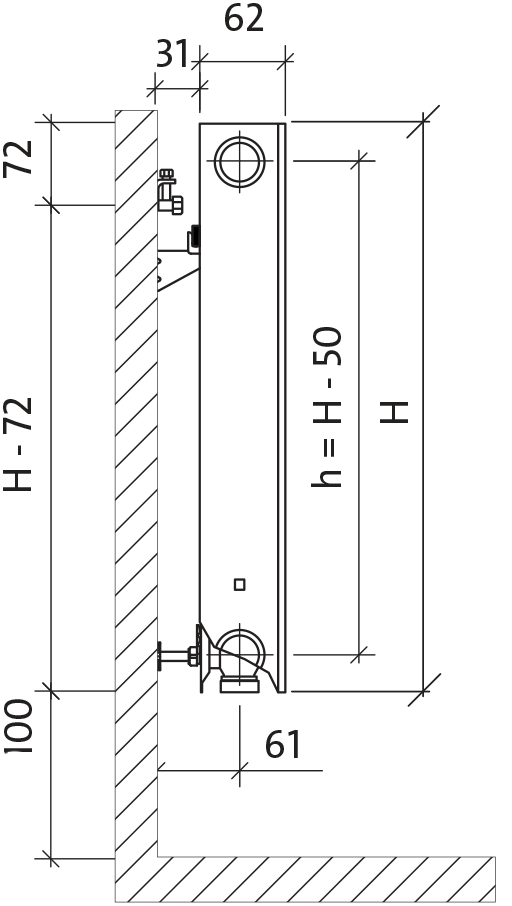

H - height: 200, 300, 500, 600, 900

L - length: 400*, 500*, 600, 700, 800, 900, 1000, 1100, 1200, 1400, 1600, 1800, 2000, 2300**, 2600**, 3000**

h - spacing of connectors

* - except for the Plan Ventil Compact model of height 200 mm

** - except for the Plan Ventil Compact model of height 900 mm

Thermal output of the radiators [W] in accordance with PN-EN 442 for the values of parameters 75/65/20 ˚C and 70/55/20˚C.

| height | 200 | 300 | 500 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length | type | FCV | FCV | FCV | ||||||||

| temp. | 21s | 22 | 33 | 44 | 11 | 22 | 33 | 11 |

21s |

22 | 33 | |

| exponent n | 1,3340 | 1,3030 | 1,3350 | 1,3640 | 1.2820 | 1.3000 | 1.3159 | 1.2827 |

1.2907 |

1.3197 | 1.3331 | |

| 400 | 75/65°C |

- |

- |

- |

- |

212 |

375 |

526 |

329 |

445 |

578 |

798 |

|

|

70/55°C |

- |

- |

- |

- |

170 |

301 |

420 |

265 |

358 |

462 |

637 |

|

500 |

75/65°C |

- |

- |

- |

- |

265 |

469 |

657 |

412 |

557 |

722 |

998 |

|

|

70/55°C |

- |

- |

- |

- |

213 | 376 | 526 | 331 |

447 |

577 | 796 |

| 600 | 75/65°C | 341 | 467 | 654 | 829 | 317 | 562 | 788 | 494 |

668 |

866 | 1198 |

| 70/55°C | 272 | 374 | 521 | 658 | 255 | 451 | 631 | 397 |

536 |

693 | 955 | |

| 700 | 75/65°C | 398 | 545 | 763 | 967 | 370 | 656 | 920 | 576 |

779 |

1011 | 1397 |

| 70/55°C | 317 | 437 | 608 | 767 | 298 | 526 | 736 | 463 |

626 |

808 | 1114 | |

| 800 | 75/65°C | 454 | 622 | 872 | 1105 | 423 | 750 | 1051 | 658 |

890 |

1155 | 1597 |

| 70/55°C | 362 | 499 | 695 | 877 | 340 | 601 | 841 | 530 |

715 |

923 | 1274 | |

| 900 | 75/65°C | 511 | 700 | 981 | 1243 | 476 | 843 | 1183 | 741 |

1002 |

1300 | 1796 |

| 70/55°C | 407 | 561 | 782 | 986 | 383 | 676 | 946 | 596 |

805 |

1039 | 1433 | |

| 1000 | 75/65°C | 568 | 778 | 1090 | 1381 | 529 | 937 | 1314 | 823 |

1113 |

1444 | 1996 |

| 70/55°C | 453 | 624 | 869 | 1096 | 426 | 752 | 1051 | 662 |

894 |

1154 | 1592 | |

| 1100 | 75/65°C | 625 | 856 | 1199 | 1519 | 582 | 1031 | 1445 | 905 |

1224 |

1588 | 2196 |

| 70/55°C | 498 | 686 | 956 | 1205 | 468 | 827 | 1156 | 728 |

983 |

1270 | 1751 | |

| 1200 | 75/65°C | 682 | 934 | 1308 | 1657 | 635 | 1124 | 1577 | 988 |

1336 |

1733 | 2395 |

| 70/55°C | 544 | 749 | 1043 | 1315 | 511 | 902 | 1261 | 794 |

1073 |

1385 | 1910 | |

| 1400 | 75/65°C | 795 | 1089 | 1526 | 1933 | 741 | 1312 | 1840 | 1152 |

1558 |

2022 | 2794 |

| 70/55°C | 634 | 873 | 1217 | 1534 | 596 | 1052 | 1471 | 927 |

1252 |

1616 | 2229 | |

| 1600 | 75/65°C | 909 | 1245 | 1744 | 2210 | 846 | 1499 | 2102 | 1317 |

1781 |

2310 | 3194 |

| 70/55°C | 725 | 998 | 1390 | 1753 | 681 | 1202 | 1682 | 1059 |

1431 |

1847 | 2547 | |

| 1800 | 75/65°C | 1022 | 1400 | 1962 | 2486 | 952 | 1687 | 2365 | 1481 |

2003 |

2599 | 3593 |

| 70/55°C | 815 | 1122 | 1564 | 1972 | 766 | 1353 | 1892 | 1192 |

1609 |

2078 | 2865 | |

| 2000 | 75/65°C | 1136 | 1556 | 2180 | 2762 | 1058 | 1874 | 2628 | 1646 |

2226 |

2888 | 3992 |

| 70/55°C | 906 | 1247 | 1738 | 2191 | 851 | 1503 | 2102 | 1324 |

1788 |

2309 | 3184 | |

| 2300 | 75/65°C | 1306 | 1789 | 2507 | 3176 | 1217 | 2155 | 3022 | 1893 |

2560 |

3321 | 4591 |

| 70/55°C | 1041 | 1434 | 1999 | 2520 | 979 | 1728 | 2417 | 1523 |

2056 |

2655 | 3661 | |

| 2600 | 75/65°C | 1477 | 2023 | 2834 | 3591 | 1375 | 2436 | 3416 | 2140 |

2894 |

3754 | 5190 |

| 70/55°C | 1178 | 1622 | 2260 | 2849 | 1106 | 1954 | 2733 | 1721 |

2325 |

3001 | 4139 | |

| 3000 | 75/65°C | 1704 | 2334 | 3270 | 4143 | 1587 | 2811 | 3942 | 2469 |

3339 |

4332 | 5988 |

| 70/55°C | 1359 | 1871 | 2607 | 3287 | 1277 | 2255 | 3153 | 1986 |

2682 |

3463 | 4776 | |

| height | 600 | 900 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| length | type | FCV | FCV | ||||||

| temp. | 11 | 21s | 22 | 33 | 11 |

21s |

22 | 33 | |

| exponent n | 1,2831 | 1,2967 | 1,3295 | 1,3417 | 1.3013 |

1.3371 |

1.3488 | 1.3612 | |

| 400 | 75/65°C | 384 | 515 | 670 | 924 | 539 |

706 |

920 | 1268 |

| 70/55°C | 309 | 413 | 535 | 736 | 432 |

563 |

732 | 1007 | |

| 500 | 75/65°C | 481 | 644 | 838 | 1155 | 674 |

883 |

1151 | 1586 |

| 70/55°C | 386 | 517 | 669 | 919 | 540 |

703 |

915 | 1258 | |

| 600 | 75/65°C | 577 | 773 | 1006 | 1385 | 808 |

1059 |

1381 | 1903 |

| 70/55°C | 464 | 620 | 802 | 1103 | 648 |

844 |

1098 | 1510 | |

| 700 | 75/65°C | 673 | 902 | 1173 | 1616 | 943 |

1236 |

1611 | 2220 |

| 70/55°C | 541 | 724 | 936 | 1287 | 756 |

985 |

1281 | 1762 | |

| 800 | 75/65°C | 769 | 1030 | 1341 | 1847 | 1078 |

1412 |

1841 | 2537 |

| 70/55°C | 618 | 827 | 1070 | 1471 | 864 |

1125 |

1464 | 2014 | |

| 900 | 75/65°C | 865 | 1159 | 1508 | 2078 | 1212 |

1589 |

2071 | 2854 |

| 70/55°C | 696 | 930 | 1204 | 1655 | 972 |

1266 |

1647 | 2265 | |

| 1000 | 75/65°C | 961 | 1288 | 1676 | 2309 | 1347 |

1765 |

2301 | 3171 |

| 70/55°C | 773 | 1034 | 1337 | 1839 | 1080 |

1407 |

1830 | 2517 | |

| 1100 | 75/65°C | 1057 | 1417 | 1844 | 2540 | 1482 |

1942 |

2531 | 3488 |

| 70/55°C | 850 | 1137 | 1471 | 2023 | 1188 |

1547 |

2013 | 2769 | |

| 1200 | 75/65°C | 1153 | 146 | 2011 | 2771 | 1616 |

2118 |

2761 | 3805 |

| 70/55°C | 928 | 1240 | 1605 | 2207 | 1296 |

1688 |

2196 | 3020 | |

| 1400 | 75/65°C | 1345 | 1803 | 2346 | 3233 | 1886 |

2471 |

3221 | 4439 |

| 70/55°C | 1082 | 1447 | 1872 | 2574 | 1512 |

1969 |

2562 | 3524 | |

| 1600 | 75/65°C | 1538 | 2061 | 2682 | 3694 | 2155 |

2824 |

3682 | 5074 |

| 70/55°C | 1237 | 1654 | 2140 | 2942 | 1728 |

2251 |

2928 | 4027 | |

| 1800 | 75/65°C | 1730 | 2318 | 3017 | 4156 | 2425 |

3177 |

4142 | 5708 |

| 70/55°C | 1391 | 1860 | 2407 | 3310 | 1944 |

2532 |

3294 | 4531 | |

| 2000 | 75/65°C | 1922 | 2576 | 3352 | 4618 | 2694 |

3530 |

4602 | 6342 |

| 70/55°C | 1546 | 2067 | 2675 | 3678 | 2160 |

2813 |

3661 | 5034 | |

| 2300 | 75/65°C | 2210 |

2962 |

3855 | 5311 | ||||

| 70/55°C | 1778 | 2377 | 3076 | 4229 | |||||

| 2600 | 75/65°C | 2499 | 3349 | 4358 | 6003 | ||||

| 70/55°C | 2010 | 2687 | 3477 | 4781 | |||||

| 3000 | 75/65°C | 2883 | 3864 | 5028 | 6927 | ||||

| 70/55°C | 2319 | 3101 | 4012 | 5516 | |||||

| height [mm]: | 200 | 300 | 500 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21s | 22 | 33 | 44 | 11 | 21s | 22 | 33 | 11 | 21s | 22 | 33 | |

| weight [kg/m]: | 12,6 | 15,5 | 22,2 | 28,8 | 11,7 | 16,7 | 19, 0 | 27,2 | 19,9 | 27,9 | 32,2 | 46,1 |

| water volume [l/m]: | 2,5 | 2,5 | 3,8 | 5,0 | 1,7 | 3,4 | 3,4 | 5,1 | 2,7 | 5,5 | 5,5 | 8,2 |

| height [mm]: | 600 | 900 | ||||||

|---|---|---|---|---|---|---|---|---|

| 11 | 21s | 22 | 33 | 11 | 21s | 22 | 33 | |

| weight [kg/m]: | 24,0 | 33,6 | 38,8 | 55,5 | 36,2 | 50,1 | 58,8 | 83,6 |

| water volume [l/m]: | 3,2 | 6,6 | 6,6 | 9,8 | 4,5 | 9,0 | 9,0 | 13,3 |

Starting from January 2011 all the bottom-supplied PURMO panel radiators are equipped with new valve Oventrop inserts with factory preset setpoint ranging from 2 to 6 depending on the size (heat output) of the particular radiator. In order to provide an easy, visual distinction of the applied valve insert, colour coding of regulatory elements of the valve inserts was implemented.

| preset setpoint | kv [m3/h] | colour | catalogue no. |

| 2 | 0,13 | white | 1651162 |

| 3 | 0,27 | black | 1651163 |

| 4 | 0,42 | green | 1651164 |

| 5 | 0,56 | blue | 1651165 |

| 6 | 0,70 | red | 1651166 |

The hydraulic characteristics of these new valve inserts are very similar to the old type (catalogue no. 101 80 80).

Should a need arise, the setpoint of every new valve insert can be changed, just like in the case of the old type inserts.

Total length of the new valve inserts was modifi ed due to an improved sealing, therefore they cannot be used in the radiators manufactured prior to January 2011 and equipped with the old-type of valve inserts.

Old-type and new-type insert |

Series of new-type inserts |

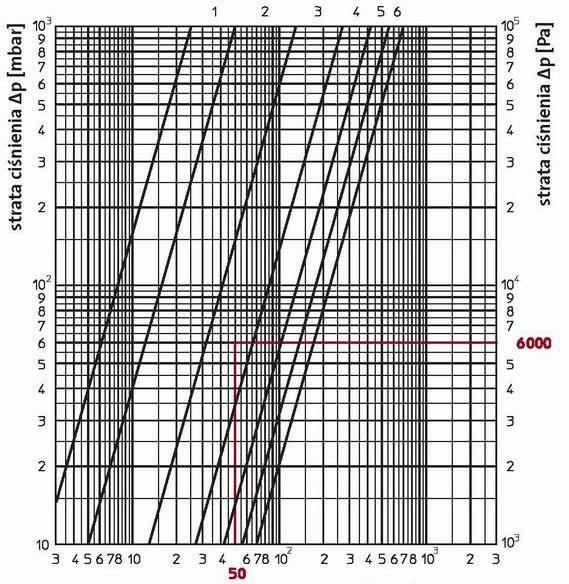

Example of preset setpoint selection

Given:

heat demand - Qc = 1160 W

rótemperature diff erence - Δt = 20 K (80/60°C)

pressure drop - Δp = 6 kPa

Δp = 6000 Pa

calculation constant - C = 1,163

calculations::

mass flow of water

q = Qc / C * Δt = 1160 / 1,163 * 20 = 50 kg/h

For the flow q = 50 kg/h and the pressure flow 6000 Pa the preset setpoint value 3 is red off the nomogram.

|

Mass flow of water q [kg/h] |

|||||||||||||||||||||

Bottom connection:This connection method is used with the bottom-supplied radiators. The supply and return line axes are always located, respectively, 80 mm and 30 mm from the side edge of the radiator. Reversed connection will cause a drop in the heat output of over 30%. |

Side connection:The most popular solution allowing for connecting radiators on either the right or the left side. The supply line should be connected to the top and the return line to the bottom connector pipe of the radiator. Reversed connection will cause a drop in the heat output of over 30%. |

Flow-through connection:Recommended for the radiators of length exceeding 2000 mm and also for the radiators of length exceeding four times their height. These connections provide even distribution of temperature over the entire length of the radiator. The supply line should be connected to the left or right connector pipe and the return line should be connected to the opposite, bottom connector pipe. Reversed connection will cause a drop in the heat output of over 30%. |

Opposite ends connectione:With this connection method, the heat output of the radiators will be approximately 10% lower than the rated heat output. This type of connection method is most commonly used with the side-supplied radiators when the heating system piping is distributed in skirting boards above the fl oor. It can also be used with the bottom-supplied radiators after the removal of a thermostatic valve insert. |

Intermediate connection:The bottom-supplied radiators can be connected simultaneously with the side and bottom connections. Possible are intermediate solutions presented at the drawings: side and flow-through. These solutions correspond to the side and flow-through connections described above. |

Front view |

Rear view (FCV11 type only) |

| type | CV11 | |

|---|---|---|

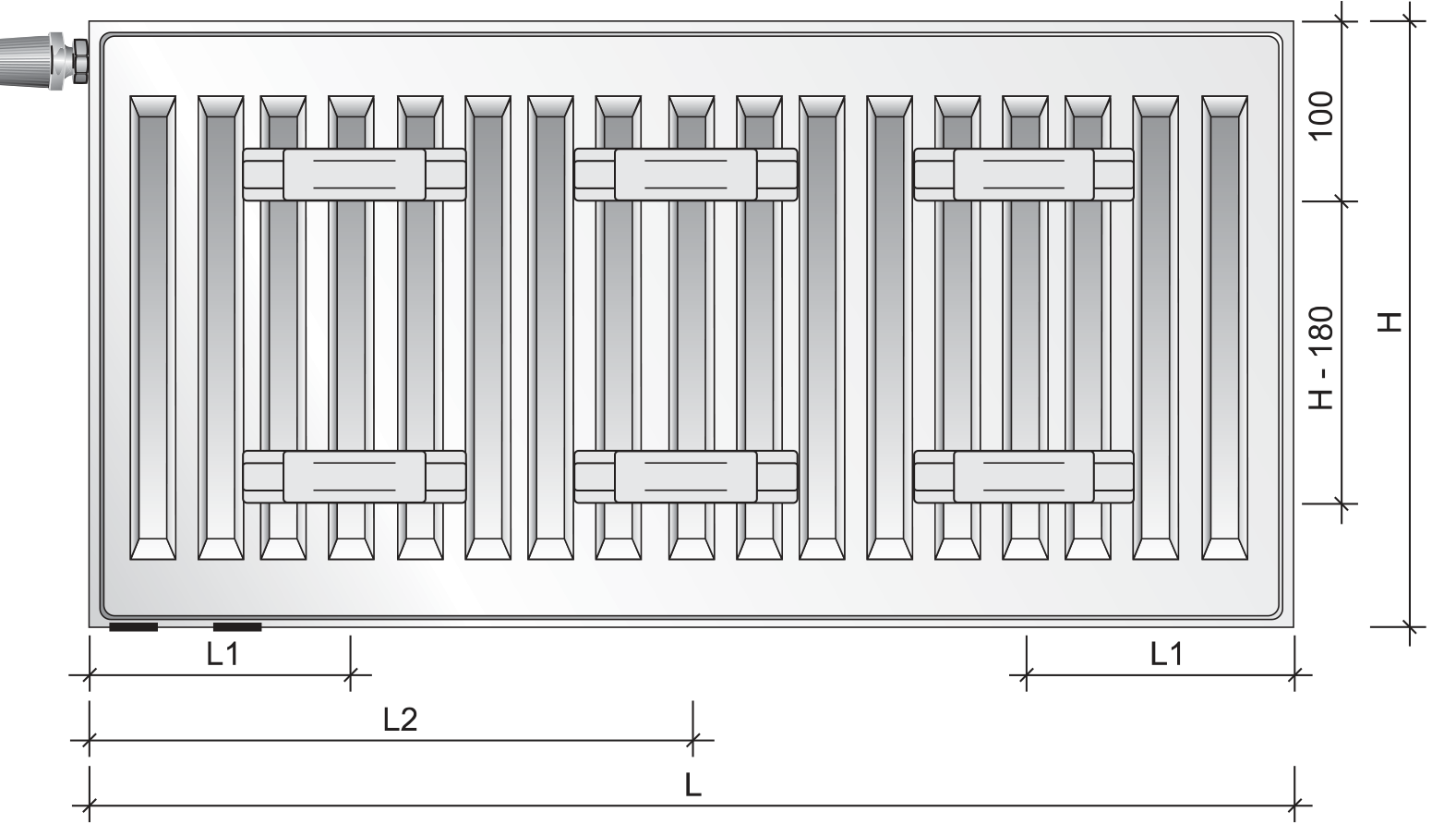

| L | L1 | L2 |

| 400-1600 | 117 | - |

| 1800 | 117 | 917 |

| 2000 | 117 | 1017 |

| 2300 | 117 | 1150 |

| 2600 | 117 | 1317 |

| 3000 | 117 | 1517 |

| height 300 - 600 mm | height 900 mm | ||

|---|---|---|---|

| length [mm] | quantity of floor brackets | length [mm] | quantity of floor brackets |

| 400 - 1800 | 2 | 400 - 1200 | 2 |

| 2000 - 2300 | 3 | 1400 - 1800 | 3 |

| 2600 - 3000 | 4 | 2000 - 3000 | 4 |

|

A set of brackets for the panel radiators with hanging lugs and the height of 300 - 900 mm - types (Only for type FCV11) |

|

A set of the Monclac MCA-D rail brackets for the panel radiators without hanging lugs and the height of 300 - 900 mm - types: FCV21s, FCV22, FCV33 |

|

Floor brackets for the FCV21s, FCV22, FCV33 type panel radiators and the height of 300 - 900 mm |

| t z | t p | ti air temperature in the heated room [˚C] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| [°C] | [°C] | 5 | 8 | 12 | 16 | 18 | 20 | 22 | 24 |

| 95 | 90 | 0,48 | 0,50 | 0,54 | 0,57 | 0,59 | 0,61 | 0,64 | 0,66 |

| 85 | 0,50 | 0,52 | 0,56 | 0,60 | 0,62 | 0,64 | 0,67 | 0,70 | |

| 80 | 0,52 | 0,55 | 0,59 | 0,63 | 0,65 | 0,68 | 0,70 | 0,73 | |

| 75 | 0,54 | 0,57 | 0,61 | 0,66 | 0,69 | 0,72 | 0,75 | 0,78 | |

| 70 | 0,57 | 0,60 | 0,65 | 0,70 | 0,73 | 0,76 | 0,79 | 0,83 | |

| 90 | 85 | 0,52 | 0,55 | 0,58 | 0,63 | 0,65 | 0,67 | 0,70 | 0,73 |

| 80 | 0,54 | 0,57 | 0,61 | 0,66 | 0,68 | 0,71 | 0,74 | 0,77 | |

| 75 | 0,57 | 0,60 | 0,64 | 0,69 | 0,72 | 0,75 | 0,78 | 0,82 | |

| 70 | 0,59 | 0,63 | 0,67 | 0,73 | 0,76 | 0,80 | 0,83 | 0,87 | |

| 65 | 0,62 | 0,66 | 0,71 | 0,77 | 0,81 | 0,85 | 0,89 | 0,93 | |

| 85 | 80 | 0,56 | 0,59 | 0,64 | 0,69 | 0,72 | 0,75 | 0,78 | 0,81 |

| 75 | 0,59 | 0,62 | 0,67 | 0,72 | 0,75 | 0,79 | 0,82 | 0,86 | |

| 70 | 0,62 | 0,65 | 0,70 | 0,77 | 0,80 | 0,84 | 0,88 | 0,92 | |

| 65 | 0,65 | 0,69 | 0,75 | 0,81 | 0,85 | 0,89 | 0,94 | 0,99 | |

| 60 | 0,68 | 0,73 | 0,79 | 0,87 | 0,91 | 0,96 | 1,01 | 1,07 | |

| 80 | 75 | 0,61 | 0,65 | 0,70 | 0,76 | 0,79 | 0,83 | 0,87 | 0,91 |

| 70 | 0,64 | 0,68 | 0,74 | 0,81 | 0,84 | 0,88 | 0,93 | 0,97 | |

| 65 | 0,68 | 0,72 | 0,78 | 0,86 | 0,90 | 0,94 | 0,99 | 1,05 | |

| 60 | 0,72 | 0,76 | 0,83 | 0,91 | 0,96 | 1,01 | 1,07 | 1,13 | |

| 55 | 0,76 | 0,81 | 0,89 | 0,98 | 1,04 | 1,10 | 1,16 | 1,24 | |

| 75 | 70 | 0,67 | 0,72 | 0,78 | 0,85 | 0,89 | 0,94 | 0,98 | 1,04 |

| 65 | 0,71 | 0,75 | 0,82 | 0,90 | 0,95 | 1,00 | 1,05 | 1,12 | |

| 60 | 0,75 | 0,80 | 0,88 | 0,97 | 1,02 | 1,08 | 1,14 | 1,21 | |

| 55 | 0,80 | 0,85 | 0,94 | 1,04 | 1,10 | 1,17 | 1,24 | 1,32 | |

| 50 | 0,85 | 0,91 | 1,01 | 1,13 | 1,20 | 1,28 | 1,37 | 1,47 | |

| 70 | 65 | 0,75 | 0,79 | 0,87 | 0,96 | 1,01 | 1,07 | 1,13 | 1,19 |

| 60 | 0,79 | 0,84 | 0,93 | 1,03 | 1,08 | 1,15 | 1,22 | 1,30 | |

| 55 | 0,84 | 0,90 | 0,99 | 1,11 | 1,17 | 1,25 | 1,33 | 1,42 | |

| 50 | 0,89 | 0,96 | 1,07 | 1,20 | 1,28 | 1,37 | 1,47 | 1,58 | |

| 65 | 60 | 0,83 | 0,89 | 0,98 | 1,10 | 1,16 | 1,23 | 1,31 | 1,40 |

| 55 | 0,88 | 0,95 | 1,05 | 1,18 | 1,26 | 1,34 | 1,43 | 1,54 | |

| 50 | 0,94 | 1,02 | 1,14 | 1,29 | 1,37 | 1,47 | 1,59 | 1,71 | |

| 60 | 55 | 0,94 | 1,01 | 1,13 | 1,27 | 1,36 | 1,45 | 1,56 | 1,68 |

| 50 | 1,00 | 1,08 | 1,22 | 1,39 | 1,48 | 1,60 | 1,73 | 1,87 | |

| 45 | 1,08 | 1,17 | 1,33 | 1,53 | 1,65 | 1,78 | 1,94 | 2,13 | |

| 55 | 50 | 1,07 | 1,16 | 1,31 | 1,50 | 1,62 | 1,75 | 1,90 | 2,07 |

| 45 | 1,15 | 1,26 | 1,43 | 1,66 | 1,80 | 1,96 | 2,15 | 2,37 | |

| 40 | 1,25 | 1,37 | 1,59 | 1,86 | 2,03 | 2,24 | 2,48 | 2,78 | |

| 50 | 45 | 1,23 | 1,36 | 1,56 | 1,82 | 1,98 | 2,17 | 2,40 | 2,67 |

| 40 | 1,34 | 1,48 | 1,73 | 2,05 | 2,25 | 2,50 | 2,79 | 3,15 | |

| 35 | 1,47 | 1,65 | 1,94 | 2,36 | 2,63 | 2,96 | 3,38 | 3,92 | |

| 45 | 40 | 1,45 | 1,62 | 1,90 | 2,28 | 2,53 | 2,83 | 3,19 | 3,66 |

| 35 | 1,60 | 1,80 | 2,15 | 2,64 | 2,96 | 3,37 | 3,89 | 4,58 | |

| 40 | 35 | 1,75 | 1,98 | 2,40 | 3,00 | 3,41 | 3,93 | 4,62 | 5,54 |

| 30 | 1,96 | 2,25 | 2,79 | 3,61 | 4,21 | 5,01 | 6,14 | 7,87 | |

The table has been prepared for n = 1,3