Your basket is empty.

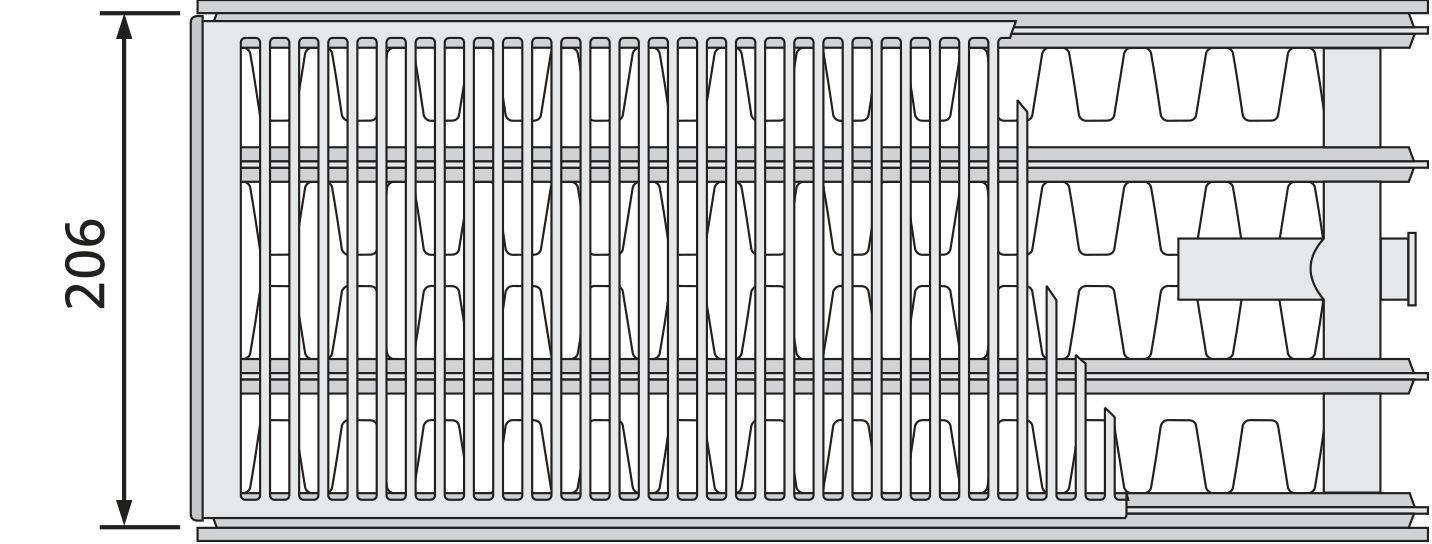

The 200-mm PURMO Plan Ventil Compact D radiator blends perfectly with contemporary architecture. Spaces with large window sections are found today not only in private residences, but also in modern office design. Versions with doublesided front plates offer the perfect heating solution for such spaces.

The high warmth generation and the space-savings offered by this radiator are additional plusses.

| Connection: | 4xGW ½" side, 2xGW ½" bottom |

| Max. working pressure: | 10 bar |

| height grzejników: | 200 mm |

| Brackets bundled with the radiator: |

brackets must be ordered separately. |

Warning: For radiator FFCV use floor brackets only

height: 200mm

length: 600, 700, 800, 900, 1000, 1200, 1400, 1600, 1800, 2000, 2300, 2600, 3000mm

Thermal output of the radiators [W] in accordance with PN-EN 442 for the values of parameters 75/65/20˚C and 70/55/20˚C

| height | 200 | ||||

|---|---|---|---|---|---|

| length | type | FFCV | |||

| temp. | 21s |

22 |

33 | 44 | |

| exponent n | 1.3060 |

1.3480 |

1.3360 | 1.3570 | |

| 600 | 75/65°C | 332 | 448 | 644 | 805 |

| 70/55°C | 266 | 356 | 513 | 639 | |

| 700 | 75/65°C | 387 | 523 | 752 | 939 |

| 70/55°C | 310 | 416 | 599 | 746 | |

| 800 | 75/65°C | 442 | 598 | 859 | 1073 |

| 70/55°C | 354 | 476 | 685 | 852 | |

| 900 | 75/65°C | 498 | 672 | 967 | 1207 |

| 70/55°C | 399 | 535 | 771 | 959 | |

| 1000 | 75/65°C | 553 | 747 | 1074 | 1341 |

| 70/55°C | 443 | 594 | 856 | 1065 | |

| 1100 | 75/65°C | 608 | 822 | 1181 | 1475 |

| 70/55°C | 487 | 654 | 941 | 1172 | |

| 1200 | 75/65°C | 664 | 896 | 1289 | 1609 |

| 70/55°C | 532 | 713 | 1028 | 1278 | |

| 1400 | 75/65°C | 774 | 1046 | 1504 | 1877 |

| 70/55°C | 620 | 832 | 1199 | 1491 | |

| 1600 | 75/65°C | 885 | 1195 | 1718 | 2146 |

| 70/55°C | 709 | 951 | 1370 | 1705 | |

| 1800 | 75/65°C | 995 | 1345 | 1933 | 2414 |

| 70/55°C | 797 | 1070 | 1541 | 1917 | |

| 2000 | 75/65°C | 1106 | 1494 | 2148 | 2682 |

| 70/55°C | 886 | 1189 | 1712 | 2130 | |

| 2300 | 75/65°C | 1272 | 1718 | 2470 | 3084 |

| 70/55°C | 1019 | 1367 | 1969 | 2450 | |

| 2600 | 75/65°C | 1438 | 1942 | 2792 | 3487 |

| 70/55°C | 1152 | 1545 | 2226 | 2770 | |

| 3000 | 75/65°C | 1659 | 2241 | 3222 | 4023 |

| 70/55°C | 1329 | 1783 | 2568 | 3196 | |

| height: | 200 | |||

|---|---|---|---|---|

| 21s | 22 | 33 | 44 | |

| weight [kg/m]: | 14,6 | 17,6 | 24,3 | 30,9 |

| water volume [dm3/m]: | 2,5 | 2,5 | 3,8 | 5,0 |

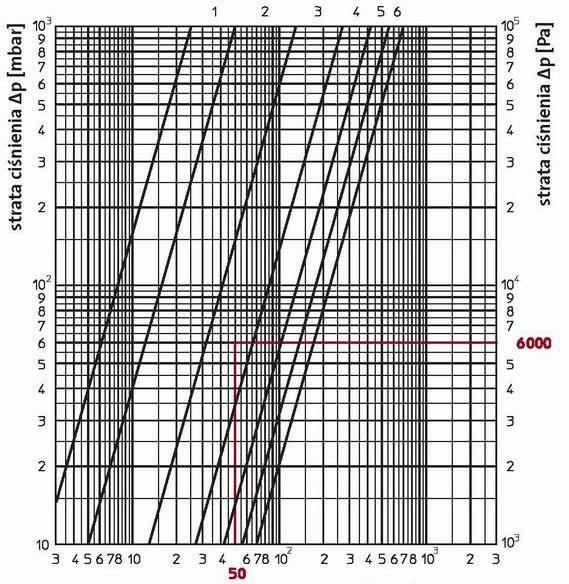

Example of preset setpoint selection

Given:

heat demand - Qc = 1160 W

rótemperature diff erence - Δt = 20 K (80/60°C)

pressure drop - Δp = 6 kPa

Δp = 6000 Pa

calculation constant - C = 1,163

calculations::

mass flow of water

q = Qc / C * Δt = 1160 / 1,163 * 20 = 50 kg/h

For the flow q = 50 kg/h and the pressure flow 6000 Pa the preset setpoint value 3 is red off the nomogram.

|

Mass flow of water q [kg/h] |

|||||||||||||||||||||

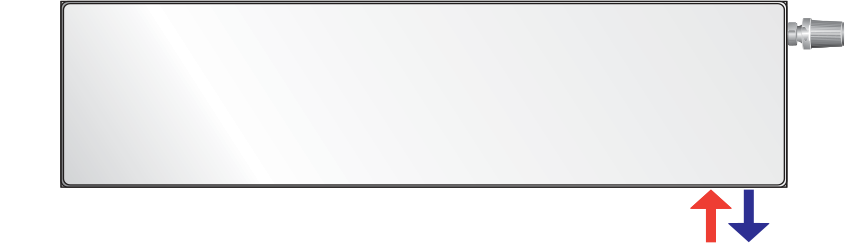

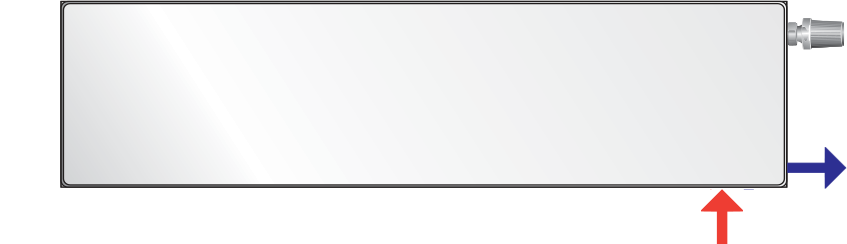

Bottom connection:This connection method is used with the bottom-supplied radiators. The supply and return line axes are always located, respectively, 80 mm and 30 mm from the side edge of the radiator. Reversed connection will cause a drop in the heat output of over 30%. |

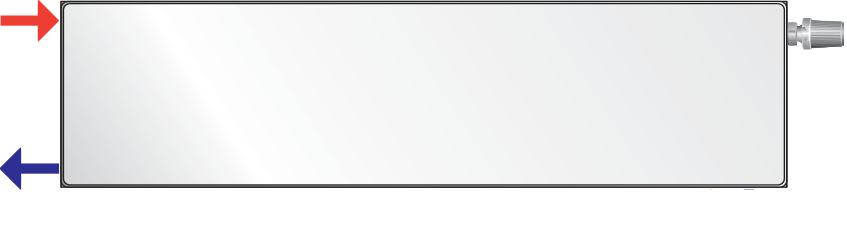

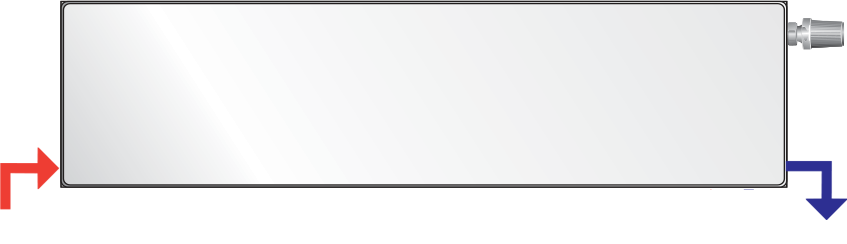

Side connection:The most popular solution allowing for connecting radiators on either the right or the left side. The supply line should be connected to the top and the return line to the bottom connector pipe of the radiator. Reversed connection will cause a drop in the heat output of over 30%. |

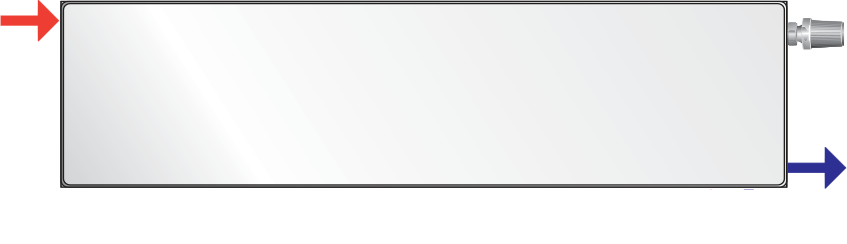

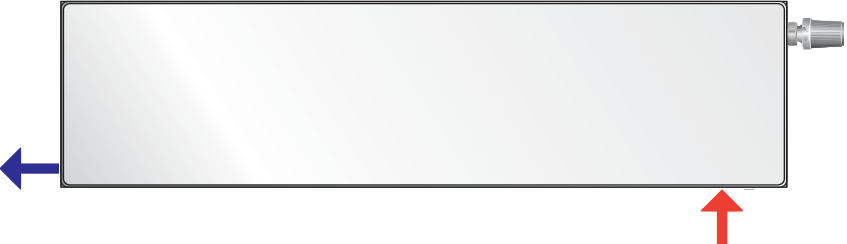

Flow-through connection:Recommended for the radiators of length exceeding 2000 mm and also for the radiators of length exceeding four times their height. These connections provide even distribution of temperature over the entire length of the radiator. The supply line should be connected to the left or right connector pipe and the return line should be connected to the opposite, bottom connector pipe. Reversed connection will cause a drop in the heat output of over 30%. |

Opposite ends connectione:With this connection method, the heat output of the radiators will be approximately 10% lower than the rated heat output. This type of connection method is most commonly used with the side-supplied radiators when the heating system piping is distributed in skirting boards above the floor. It can also be used with the bottom-supplied radiators after the removal of a thermostatic valve insert. |

Intermediate connection:The bottom-supplied radiators can be connected simultaneously with the side and bottom connections. Possible are intermediate solutions presented at the drawings: side and flow-through. These solutions correspond to the side and flow-through connections described above. |

Top view |

Front view |

| height 200 mm | |

|---|---|

| Panel radiator length mm | quantity of brackets |

| 600 – 1600 | 2 |

| 1800 – 2300 | 3 |

| 2600 – 300 | 4 |

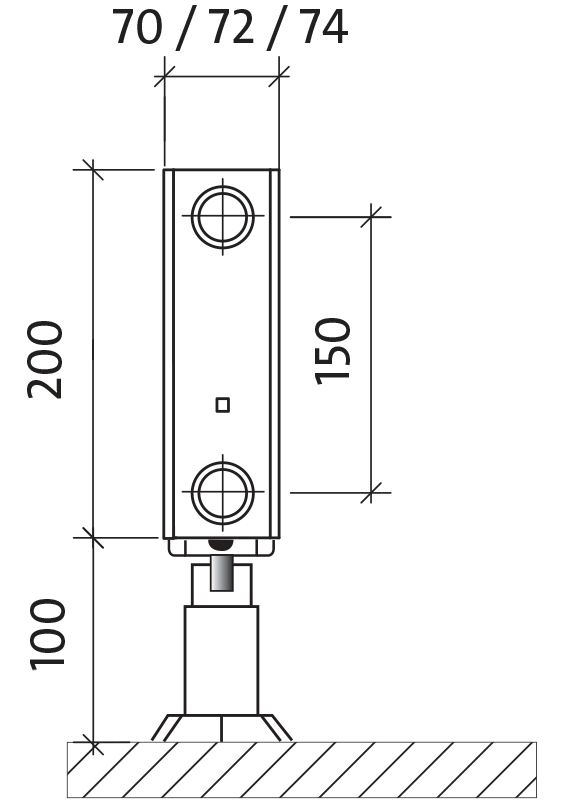

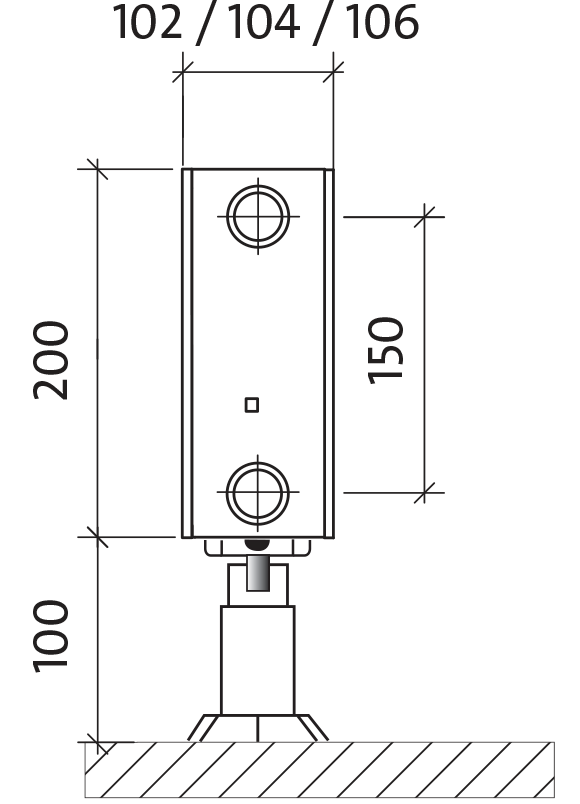

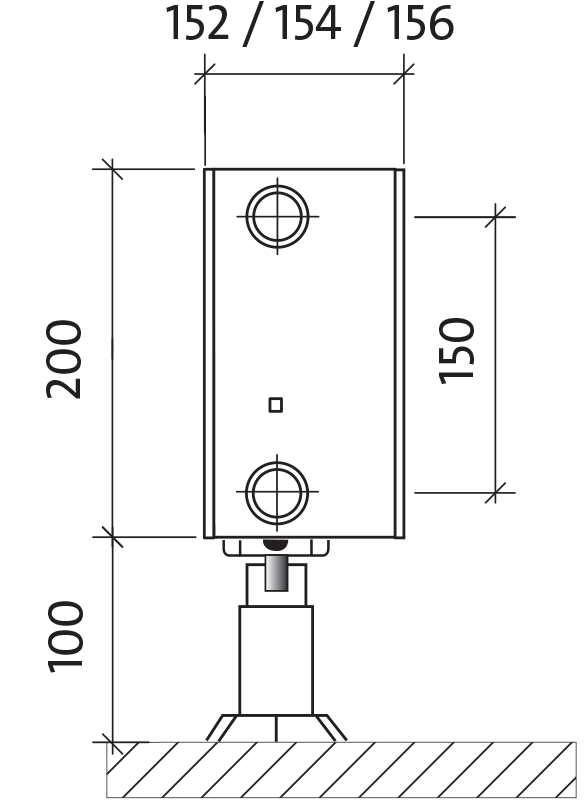

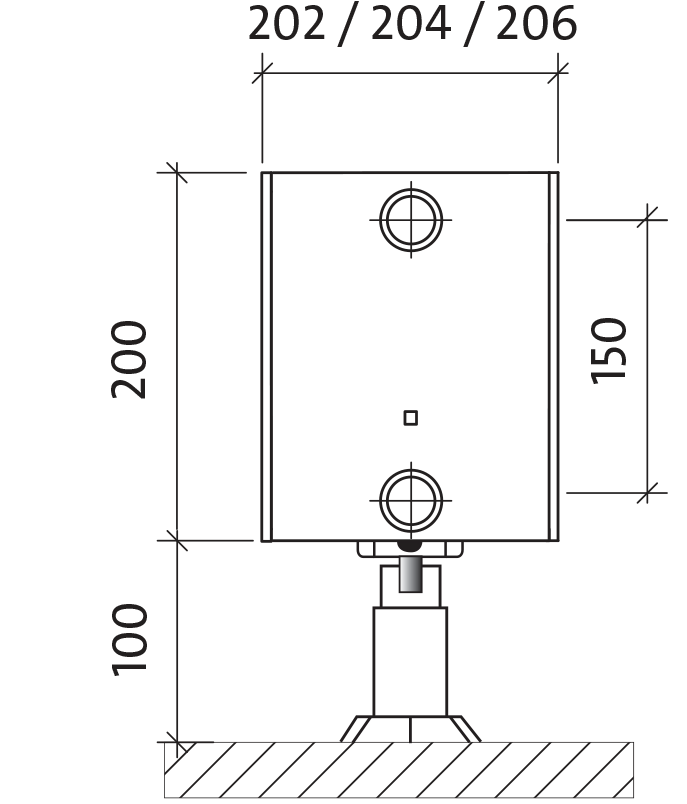

Brackets floor for the panel radiators of height 200 mm

|

The floor brackets for the panel radiators of height 200 mm: FFCV21s, FFCV22, FFCV33, FFCV44 |

| t z | t p | ti air temperature in the heated room [˚C] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| [°C] | [°C] | 5 | 8 | 12 | 16 | 18 | 20 | 22 | 24 |

| 95 | 90 | 0,48 | 0,50 | 0,54 | 0,57 | 0,59 | 0,61 | 0,64 | 0,66 |

| 85 | 0,50 | 0,52 | 0,56 | 0,60 | 0,62 | 0,64 | 0,67 | 0,70 | |

| 80 | 0,52 | 0,55 | 0,59 | 0,63 | 0,65 | 0,68 | 0,70 | 0,73 | |

| 75 | 0,54 | 0,57 | 0,61 | 0,66 | 0,69 | 0,72 | 0,75 | 0,78 | |

| 70 | 0,57 | 0,60 | 0,65 | 0,70 | 0,73 | 0,76 | 0,79 | 0,83 | |

| 90 | 85 | 0,52 | 0,55 | 0,58 | 0,63 | 0,65 | 0,67 | 0,70 | 0,73 |

| 80 | 0,54 | 0,57 | 0,61 | 0,66 | 0,68 | 0,71 | 0,74 | 0,77 | |

| 75 | 0,57 | 0,60 | 0,64 | 0,69 | 0,72 | 0,75 | 0,78 | 0,82 | |

| 70 | 0,59 | 0,63 | 0,67 | 0,73 | 0,76 | 0,80 | 0,83 | 0,87 | |

| 65 | 0,62 | 0,66 | 0,71 | 0,77 | 0,81 | 0,85 | 0,89 | 0,93 | |

| 85 | 80 | 0,56 | 0,59 | 0,64 | 0,69 | 0,72 | 0,75 | 0,78 | 0,81 |

| 75 | 0,59 | 0,62 | 0,67 | 0,72 | 0,75 | 0,79 | 0,82 | 0,86 | |

| 70 | 0,62 | 0,65 | 0,70 | 0,77 | 0,80 | 0,84 | 0,88 | 0,92 | |

| 65 | 0,65 | 0,69 | 0,75 | 0,81 | 0,85 | 0,89 | 0,94 | 0,99 | |

| 60 | 0,68 | 0,73 | 0,79 | 0,87 | 0,91 | 0,96 | 1,01 | 1,07 | |

| 80 | 75 | 0,61 | 0,65 | 0,70 | 0,76 | 0,79 | 0,83 | 0,87 | 0,91 |

| 70 | 0,64 | 0,68 | 0,74 | 0,81 | 0,84 | 0,88 | 0,93 | 0,97 | |

| 65 | 0,68 | 0,72 | 0,78 | 0,86 | 0,90 | 0,94 | 0,99 | 1,05 | |

| 60 | 0,72 | 0,76 | 0,83 | 0,91 | 0,96 | 1,01 | 1,07 | 1,13 | |

| 55 | 0,76 | 0,81 | 0,89 | 0,98 | 1,04 | 1,10 | 1,16 | 1,24 | |

| 75 | 70 | 0,67 | 0,72 | 0,78 | 0,85 | 0,89 | 0,94 | 0,98 | 1,04 |

| 65 | 0,71 | 0,75 | 0,82 | 0,90 | 0,95 | 1,00 | 1,05 | 1,12 | |

| 60 | 0,75 | 0,80 | 0,88 | 0,97 | 1,02 | 1,08 | 1,14 | 1,21 | |

| 55 | 0,80 | 0,85 | 0,94 | 1,04 | 1,10 | 1,17 | 1,24 | 1,32 | |

| 50 | 0,85 | 0,91 | 1,01 | 1,13 | 1,20 | 1,28 | 1,37 | 1,47 | |

| 70 | 65 | 0,75 | 0,79 | 0,87 | 0,96 | 1,01 | 1,07 | 1,13 | 1,19 |

| 60 | 0,79 | 0,84 | 0,93 | 1,03 | 1,08 | 1,15 | 1,22 | 1,30 | |

| 55 | 0,84 | 0,90 | 0,99 | 1,11 | 1,17 | 1,25 | 1,33 | 1,42 | |

| 50 | 0,89 | 0,96 | 1,07 | 1,20 | 1,28 | 1,37 | 1,47 | 1,58 | |

| 65 | 60 | 0,83 | 0,89 | 0,98 | 1,10 | 1,16 | 1,23 | 1,31 | 1,40 |

| 55 | 0,88 | 0,95 | 1,05 | 1,18 | 1,26 | 1,34 | 1,43 | 1,54 | |

| 50 | 0,94 | 1,02 | 1,14 | 1,29 | 1,37 | 1,47 | 1,59 | 1,71 | |

| 60 | 55 | 0,94 | 1,01 | 1,13 | 1,27 | 1,36 | 1,45 | 1,56 | 1,68 |

| 50 | 1,00 | 1,08 | 1,22 | 1,39 | 1,48 | 1,60 | 1,73 | 1,87 | |

| 45 | 1,08 | 1,17 | 1,33 | 1,53 | 1,65 | 1,78 | 1,94 | 2,13 | |

| 55 | 50 | 1,07 | 1,16 | 1,31 | 1,50 | 1,62 | 1,75 | 1,90 | 2,07 |

| 45 | 1,15 | 1,26 | 1,43 | 1,66 | 1,80 | 1,96 | 2,15 | 2,37 | |

| 40 | 1,25 | 1,37 | 1,59 | 1,86 | 2,03 | 2,24 | 2,48 | 2,78 | |

| 50 | 45 | 1,23 | 1,36 | 1,56 | 1,82 | 1,98 | 2,17 | 2,40 | 2,67 |

| 40 | 1,34 | 1,48 | 1,73 | 2,05 | 2,25 | 2,50 | 2,79 | 3,15 | |

| 35 | 1,47 | 1,65 | 1,94 | 2,36 | 2,63 | 2,96 | 3,38 | 3,92 | |

| 45 | 40 | 1,45 | 1,62 | 1,90 | 2,28 | 2,53 | 2,83 | 3,19 | 3,66 |

| 35 | 1,60 | 1,80 | 2,15 | 2,64 | 2,96 | 3,37 | 3,89 | 4,58 | |

| 40 | 35 | 1,75 | 1,98 | 2,40 | 3,00 | 3,41 | 3,93 | 4,62 | 5,54 |

| 30 | 1,96 | 2,25 | 2,79 | 3,61 | 4,21 | 5,01 | 6,14 | 7,87 | |

The table has been prepared for n = 1,3