- Contents

- Interview with Mikko Iivonen

- It’s time to change our way of thinking

- How insulation influences heating efficiency

- Interview with Professor Christer Harryson

- The increasing use of low temperature water systems

- Interview with Professor Dr. Jarek Kurnitski

- Significant proof

- Choosing a heat emitter

- Interview with Elo Dhaene

- Benefits to the end user

- Heat pump and condensing boiler > Both heat sources in modern and insulated buildings are efficient ways to supply low-temperature water systems

- Efficiency of heat generation > Both heat sources also function perfectly with low temperature radiators

- Energy refurbishment of buildings > Buildings heated by low temperature radiators systems consume less total energy than underfloor heated buildings

- Improving the energy efficiency of older buildings is a more effective way of saving more energy

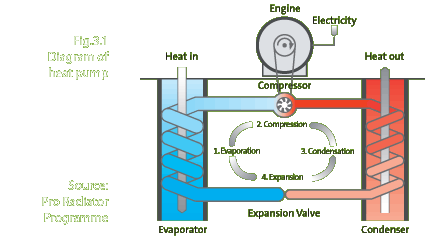

Heat pump

Thanks to lower heat demand, homes and offices now need less heating energy to keep them warm. This makes the heat pump an ideal companion in a modern heating system. Temperature a few metres beneath the ground is fairly constant throughout the year, around 10°C. Geothermal heat pumps take advantage of this, with the help of a loop of tubing – the vertical ground loop – buried 100-150m under the soil or alternatively the horizontal grid closer to the surface. Typically a water/ethanol mix is pumped through this loop, where heat exchange occurs before the warmed fluid returns to the pump. From there the heat is transferred to the heating system. Air-water heat pumps are also good alternatives. They can use outdoor air or/and ventilation exhaust air as a heat source.

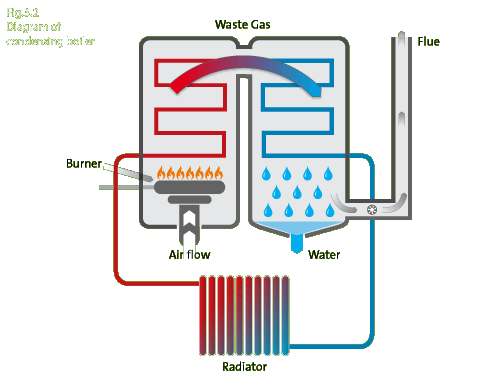

Condensing boiler

Traditional boilers had a single combustion chamber enclosed by the waterways of the heat exchanger where hot gases passed through. These gases were eventually expelled through the flue, located at the top of the boiler, at a temperature of around 200°C. These are no longer fitted new, but in the past many were fitted in existing homes. Condensing boilers, on the other hand, first allow the heat to rise upwards through the primary heat exchanger; when at the top the gases are rerouted and diverted over a secondary heat exchanger.

In condensing boilers, fuel (gas or oil) is burned to heat water in a circuit of piping, which can include the building’s radiators. When the fuel is burned, steam is one byproduct of the combustion process, and this steam is condensed into hot water. Energy is extracted and heat gained from this return flow water, before it is returned to the circuit (fig. 3.2). While either gas or oil can be used, gas is more efficient since the exhaust of the heated water in a gas system condenses at 57°C, whereas in an oil-based system this does not occur until 47°C. An additional advantage of a gas system is its higher water content.

For all condensing boilers, there is significant energy saving through the efficient use of the combusted fuel: exhaust gas is around 50°C , compared with traditional boilers, whose flue gases escape unused at 200°C.

Both heat sources are efficient ways to supply lowtemperature water systems

Both heat pumps and condensing boilers are efficient ways to supply low-temperature water systems in modern and insulated buildings, making them ideally suited to radiators, which can be used with any heat source, including renewable energy.

Efficiency of heat generation

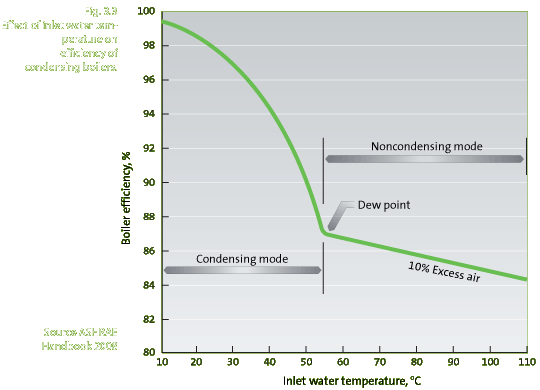

Condensing boilers can function in the condensing mode when the inlet water temperatures to the heating network remain below 55°C. Efficiency increase, compared to a standard boiler, is around 6% for oil and around 11% for gas.

Heat pumps also function perfectly with low temperature radiators

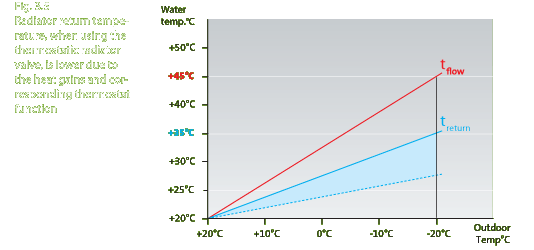

Heat pumps are often assumed to be specific to underfloor heating, when in fact they also function perfectly with low temperature radiators. EN 14511-2 standard describes a simplified method for calculating the seasonal performance factor, SPF, taking only the heating system inlet water temperature into account. This way of calculation can give reasonably accurate SPF values for underfloor heating, where the inlet and return water temperature differences are typically small, often less than 5 K. This simplified method is not applicable for radiator heating, where the inlet and return water temperature differences are larger. For these calculation purposes EN 14511-2 shows an accurate method, also taking into account the return water temperature. In conjunction with SPF is COPa, the annual coefficient of performance, which describes the heat pump efficiency, when the season length is one year.

Note: The primary energy need of a condensing boiler with solar used for heating and warm water resembles that of the sole water heat pump. Source: ZVSHK, Wasser Wärme, Luft, Ausgabe 2009/2010

Fig. 3.4 Table of COPa values for different design water temperatures, combined heating and domestic hot water production, DHW, and heating only. Also shown are the resulting condensing temperatures. The reference building is a modern single-family house in Munich, equipped with electric ground source heat pump. COP values are verified by laboratory measurements (Bosch 2009).

Fig. 3.4

Annual Coefficient of Performance: COPa

COPa = Quantity of heat delivered by heat pump divided by the energy needed to drive the process over a one year period

| Design temps |

Condensing temp |

COPa combined |

COPa heating only |

| 70/55/20 | 62,4 | 2,8 | 3,0 |

| 55/45/20 | 49,2 | 3,2 | 3,6 |

| 60/40/20 | 49,0 | 3,2 | 3,6 |

| 50/40/20 | 44,0 | 3,3 | 3,8 |

| 45/35/20 | 38,8 | 3,5 | 4,1 |

| 50/30/20 | 38,7 | 3,5 | 4,1 |

| 40/30/20 | 33,7 | 3,6 | 4,4 |

| 35/28/20 | 30,2 | 3,8 | 4,6 |

Electric ground-source heat pump. COPa figures from reference building (IVT Bosch Thermoteknik AB)

It is highly favourable to use low temperatures with radiators, when using heat pumps as a heat generator

The results show that it is highly favourable to use low temperatures with radiators, when using heat pumps as a heat generator. Heat pumps for small houses are often combined with DHW production. When comparing the combined COPa values, we can see that design water temperatures of a typical LTR system (45/35) give around 10% higher heat pump efficiency than the 55/45 system. The difference between the 45/35 system and for typical underfloor heating 40/30 system is around 3%, and 9% when compared with the 35/28 system.

Energy refurbishment of buildings

Buildings heated by low temperature radiators systems consume less total energy than underfloor heated buildings

Improving the energy efficiency of older buildings is a more effective way of saving more energy

In short, buildings heated by low temperature radiator systems consume less total energy than underfloor heated buildings, even when using heat pumps as a heat generator. Differences of COP values are compensated by the higher energy efficiency of the low temperature radiators.

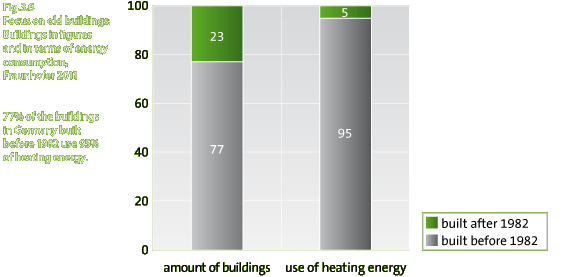

Buildings, particularly residential buildings are currently in a upward spiral of energy consumption. Energy used in buildings is the biggest single energy consumption sector in Europe. Logically our energy-saving activities should be directed at reducing energy use in buildings. Interestingly though, modern buildings (new or well-renovated) are not actually the problem when it comes to energy consumption. If we take German building stock as an example, the number of newer buildings built after 1982 make up 23% of the country’s total stock, but consume only 5% of the heating energy. In other words, improving the energy efficiency of older buildings is a more effective way of saving more energy.

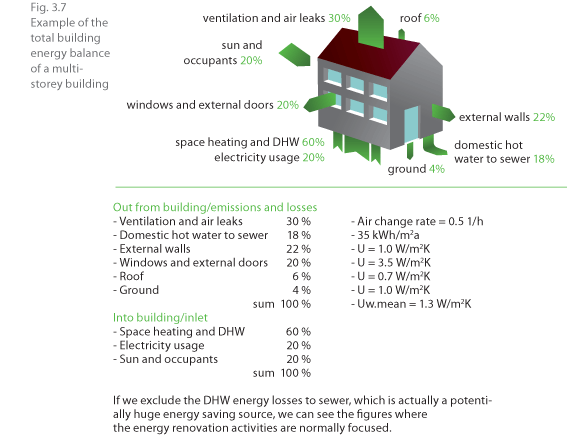

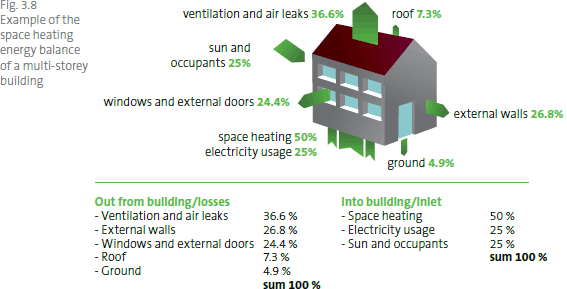

A building’s total energy balance consists of energy flows into and out of the building

A building’s total energy balance consists of energy flows into and out of the building. Potential cooling energy is not included in these figures. The energy flows of the example building can be defined as follows:

These figures are example values for older multi-storey buildings, where the typical demand of space heating energy, including transmission losses and ventilation, is around 240 kWh/m2a. If we want to make an approximation of other house types, we should take into consideration the following features: surface sizes, U-values and ventilation air flow rates. For instance, a single-storey house has relatively much higher losses through the roof and to the ground than a multi-storey building.

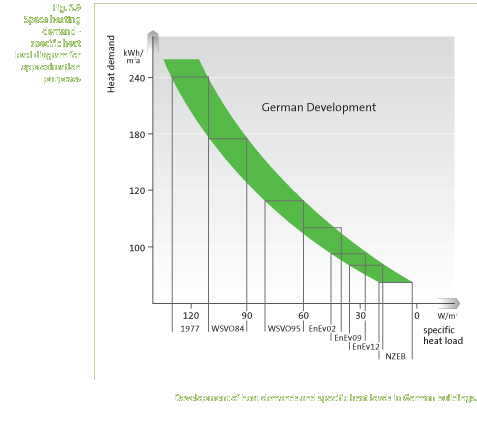

Space heating energy demand and specific heat loads

We can make a correlation of space heating demands, kWh/m2a, and the specific heat loads, W/m2, based on the available statistics for different German building energy requirement periods.

Let us consider the reference multi-storey building if it is renovated, and recalculate. Specific heat load in the original stage can be rated from the diagram Fig. 3.9 at space heating demand of 240 kWh/m2a. Heat load value is about 120 W/m2. The building envelope and insulation will be improved. The new U-values of the building elements will be:

| - External walls | U = 0,24 W/m2K |

| - Windows and exterior doors | U = 1,3 W/m2K |

| - Roof | U = 0,16 W/m2K |

| - Ground | U = 0,5 W/m2K |

| Uw.mean = 0,40 W/m2K |

If there are no surface area changes in the building elements and the ventilation air-flow rates remain unchanged as well, we can calculate the influence of the improved insulation. The transmission losses will be reduced to 31%, when the area weighted U-values, Uw. mean = 1.3 W/m2K go down to Uw.mean =0.40 W/m2K. Thus the ventilation remains unchanged and the total heat loss reduction will be only 44.3%.

Note: This type of widespread insulation improvement project is often motivated by a need for better windows and a more attractive façade or by need of higher thermal comfort and healthier indoor environment..

The new share of losses will be:

| - Ventilation and infiltration | 65,1 % |

| - External walls | 11,4 % |

| - Windows and exterior doors | 16,1 % |

| - Roof | 3,6% |

| - Ground | 4,4% |

| sum 100% |

The heat load will be 44.3% smaller than in the original case. New specific load is about 67 W/m2, and from Fig. 3.9 we can see that the corresponding heating demand value is about 100 kWh/m2a.